Which Rock Sliders are Right for You?

You’ve decided it’s time to invest in rock sliders — you know, those thick pieces of steel that offer durable protection to the rocker panel areas on your Jeep to keep it safe from your rock crawling experience?

There are various types of running boards and side steps that you can add to your Jeep, but these are typically used for aesthetic purposes or to make getting in and out of the vehicle a little easier. These won’t protect your rocker panels while off-roading.

Now, Fab Fours has introduced rock sliders into their body armor product line so you can outfit your Jeep with thick steel protection for those rock crawling activities.

But how do you know which type of rock slider to invest in? After all, there’s a few variations that might be the right functional setup for your Jeep, but is it also the right look and feel you were hoping for?

Here’s what to look for in your next set of rock sliders.

Rock Sliders

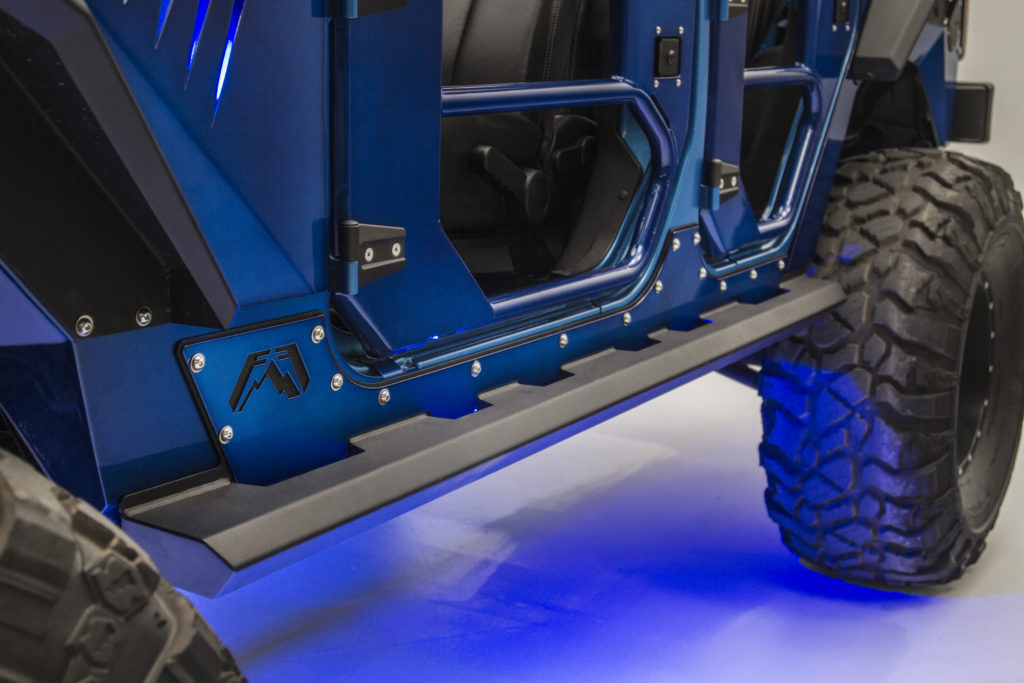

Fab Fours’ Rock Sliders offer an aggressive design that simultaneously protects the sides of your Jeep JL or Jeep Gladiator while also offering running board functionality. Their lightweight steel construction also accommodates up to three Rigid Rock Lights per side of the Jeep, which promises 100% light coverage from wheel to wheel. It’s the perfect combination of aesthetics and functionality, and protects your 4×4 on and off-roading.

Hardcore Rock Sliders

If you’re going to take your Jeep JK across difficult terrain, the Hardcore Rock Sliders are the perfect solution. Fab Fours matched the radius of the JK body with a vertical plate, creating protective armor that can withstand even the toughest of conditions. And the top surface even doubles as an entry step, so it’s easier than ever to mount or dismount your vehicle.

LED Light Rock Sliders

On top of providing unparalleled protection, the LED Light Rock Sliders for your Jeep JK will double as an entry step and provide full lighting along each side of the vehicle. The set ties into the body mounts in twelve places on each side to deliver the most rock panel protection available. Fab Fours’ signature “knife edge” design gives your Jeep a unique daytime look while offering full visibility for night-time rock crawling activities.

Tube Rock Sliders

Tube Rock Sliders are the perfect solution for those dedicated trail riders looking for a solution to protect their Jeep JL or Jeep Gladiator. The solid tube design offers total protection without modifying the body of the vehicle. These are known for their superior strength and durability for the most zealous all-terrain adventurers. Even the harshest of off-road conditions can’t hurt your 4×4 thanks to this lightweight set of rock sliders that sit high and tight to the frame.

Much like other Fab Fours off-road modification options, these rock sliders are seamless to install — it typically takes no more than an hour or two! And since all Fab Fours’ products are manufactured right here in the United States, you can rest assured that you’re getting the best quality products delivered every time.